Copyright © Dongguan Yuan Han Industrial Co., Ltd. All Rights Reserved. Site Map

- +86-18128595705

- ricowang@silicagelrubber.com

- Room 101, No. 12, Baifeng 2nd Street, Baidi Community, Zhangmutou Town, Dongguan City, Guangdong Province

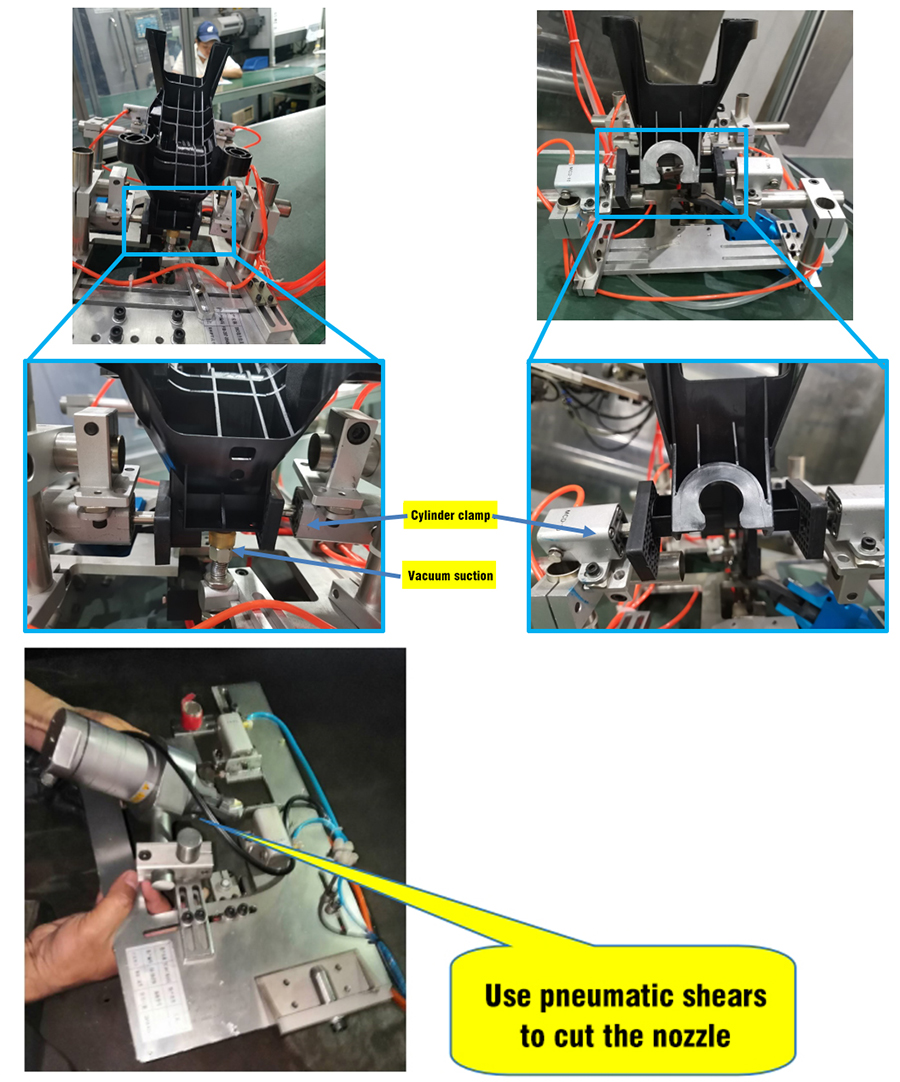

The customer company uses injection molding to produce plastic structural parts. Because the product weighs 288g and the nozzle diameter is 6mm, a dedicated person is required to take the product out of the machine and remove the nozzle material of the product during operation. The nozzle diameter is large, manual cutting is time-consuming and labor-intensive, and it is easy to fatigue.