Automated production to improve production efficiency

Publish Time: 2024-12-27

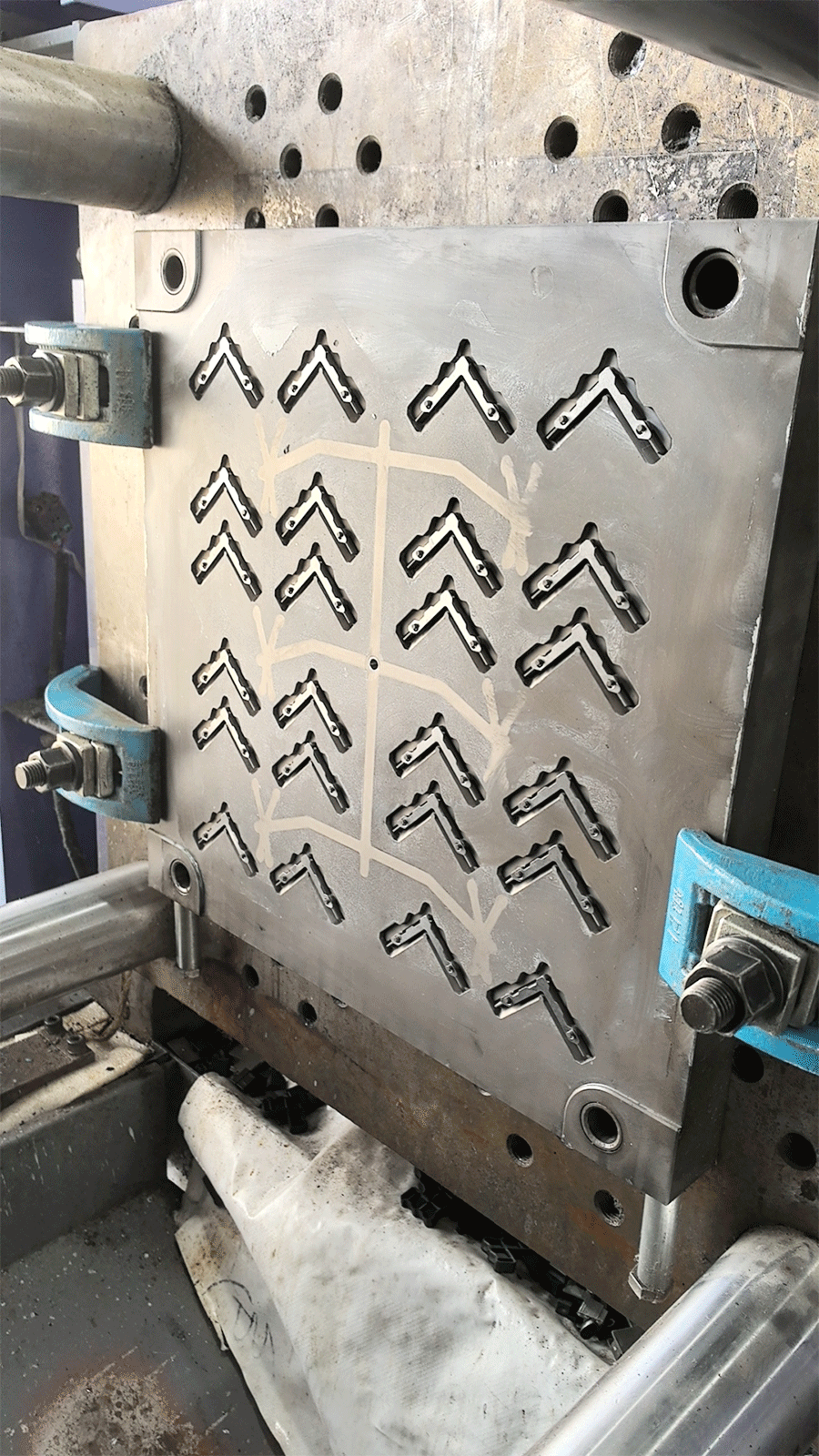

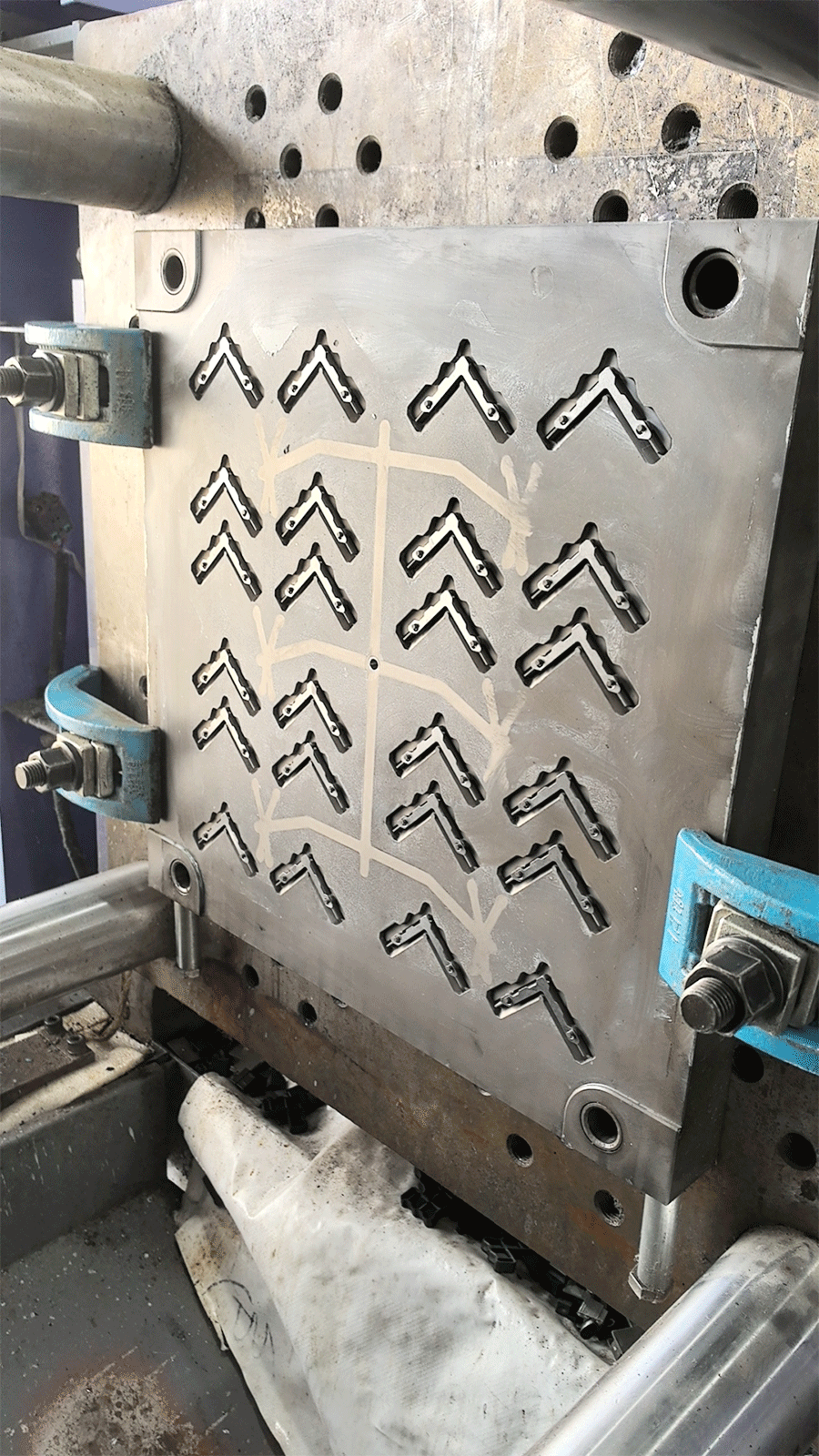

The customer company produces right-angle fixing buckles. Due to product structural requirements, it is necessary to implant reinforcing iron sheets in the fixing buckles. Each set of molds needs to contain 24 iron sheets. Manual placement of iron sheets is time-consuming and has low production efficiency.

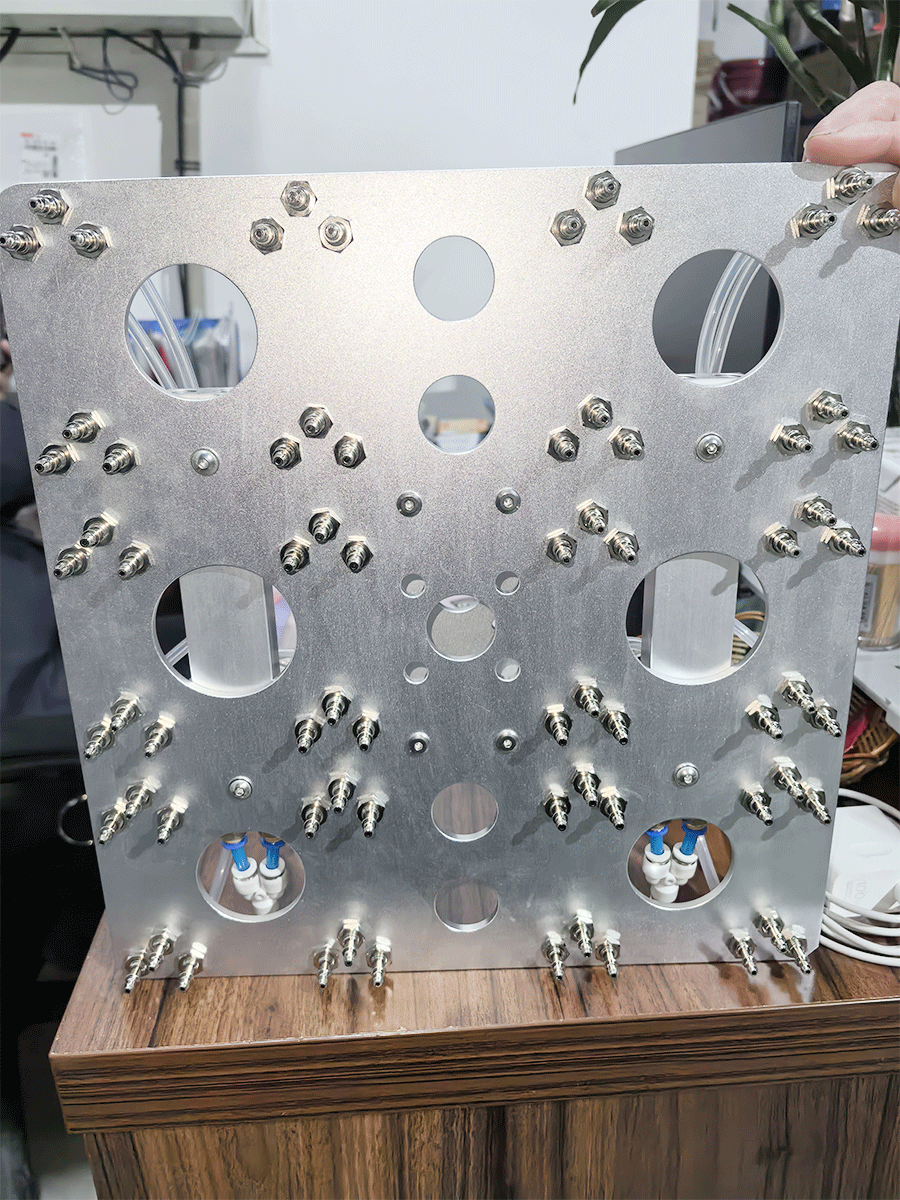

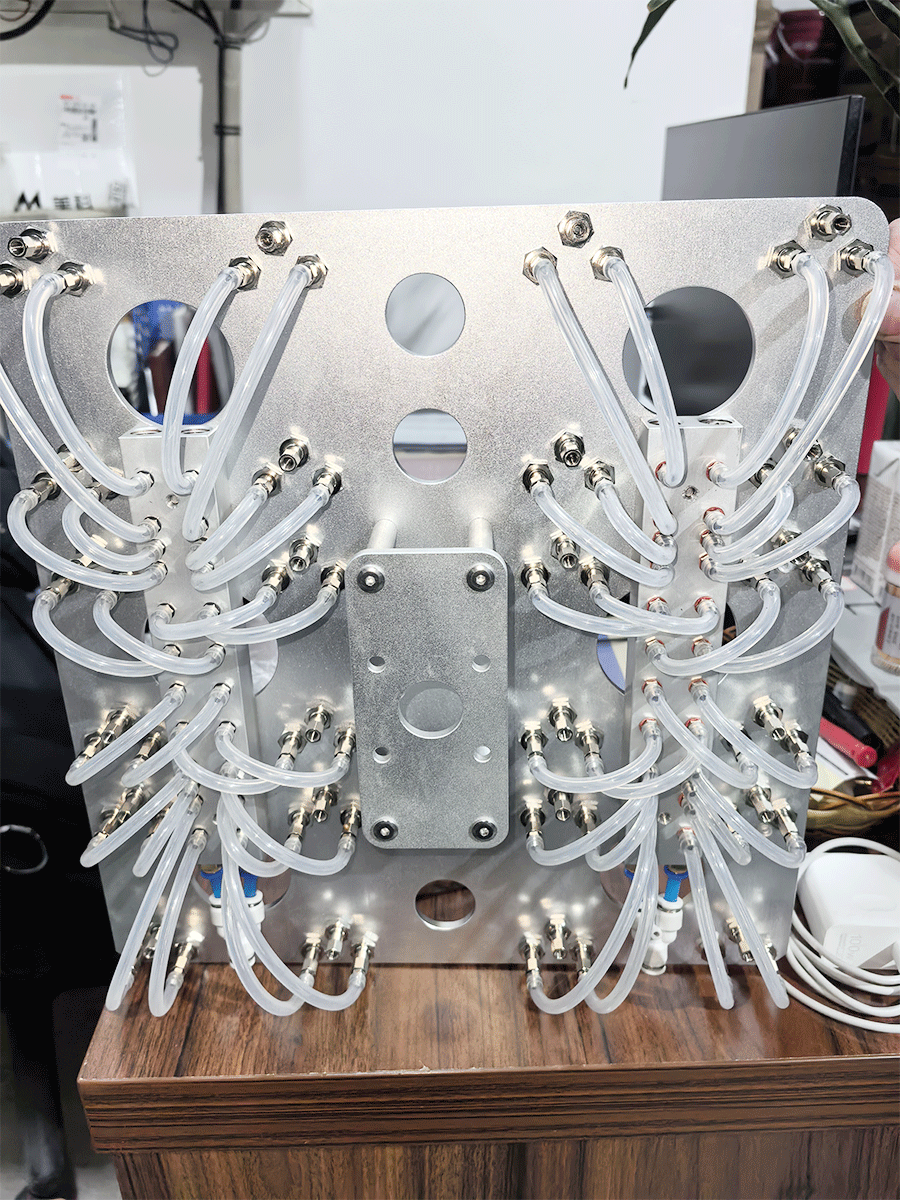

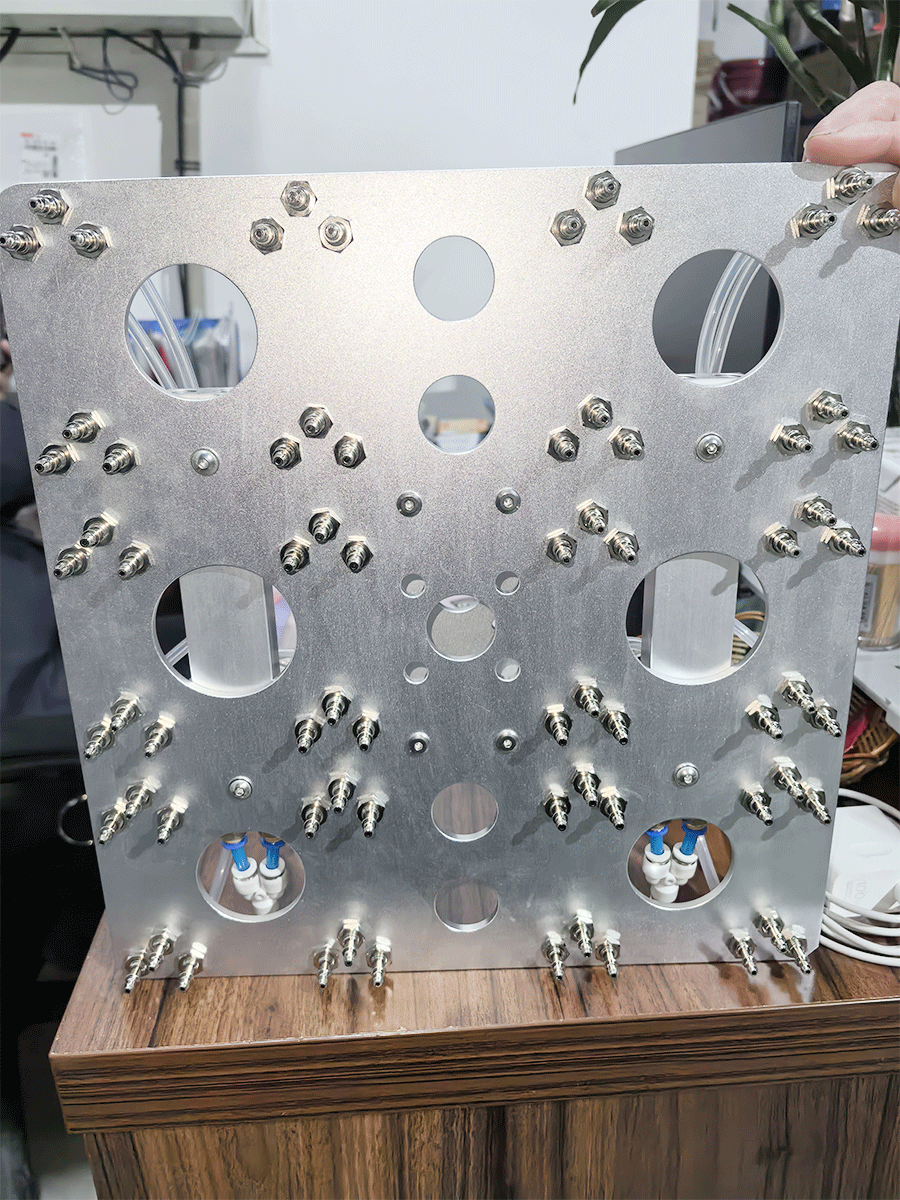

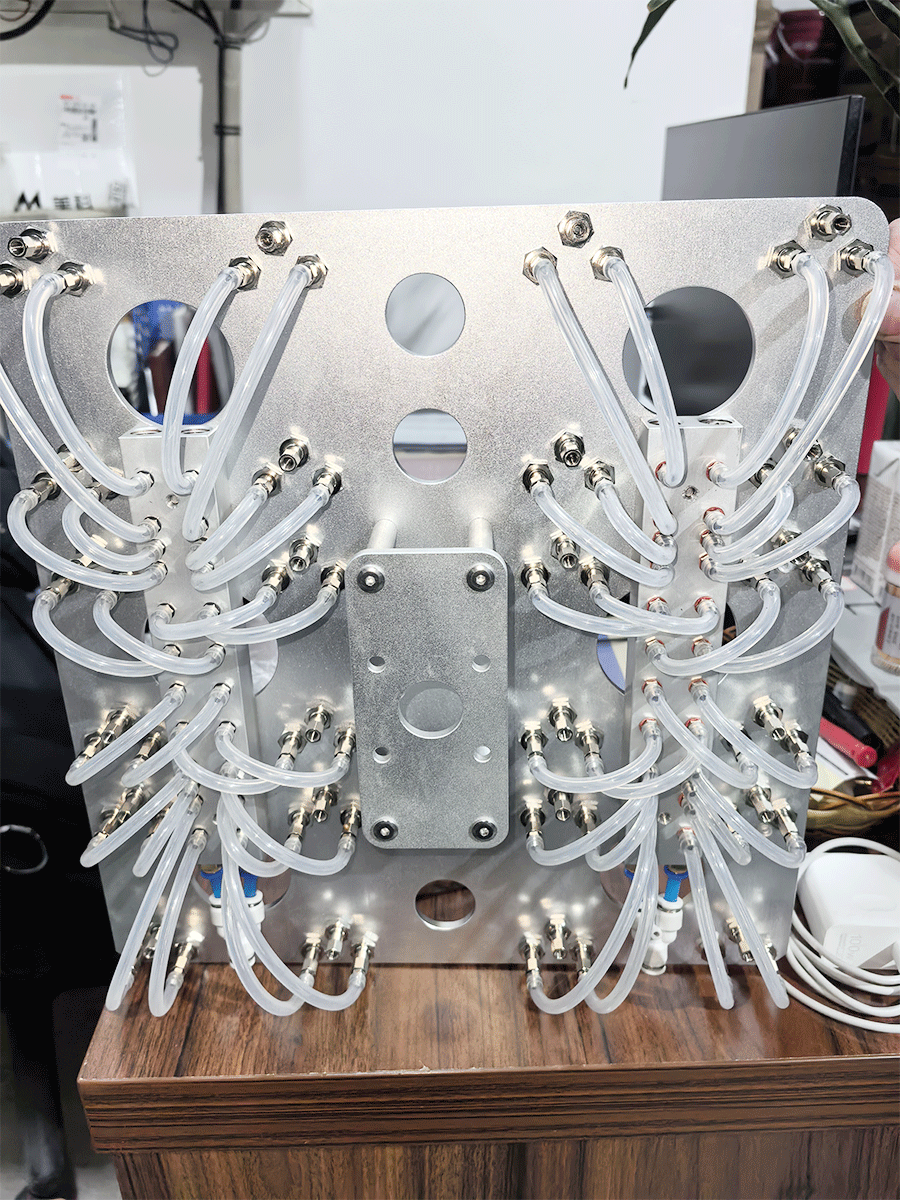

After communicating with the customer, our engineers first made a visual pick-up and placement table. According to the mold arrangement method, the iron sheets are neatly placed 1:1 outside the mold, and then the manipulator is used to combine the hardware suction cup fixture to pick up 24 right-angle iron sheets at one time and put them into the mold to achieve automated operation.

After communicating with the customer, our engineers first made a visual pick-up and placement table. According to the mold arrangement method, the iron sheets are neatly placed 1:1 outside the mold, and then the manipulator is used to combine the hardware suction cup fixture to pick up 24 right-angle iron sheets at one time and put them into the mold to achieve automated operation.

After the customer introduced the automated production plan, unmanned operation was realized, and the original iron sheet placement time was increased from 340 seconds to 25 seconds, and the production efficiency was increased by 14 times.

After the customer introduced the automated production plan, unmanned operation was realized, and the original iron sheet placement time was increased from 340 seconds to 25 seconds, and the production efficiency was increased by 14 times.